Magnesium is a silvery white metal that is lightweight, strong and dimensionally stable. It is ductile, malleable when heated and has superior resistance to impact. Damping characteristics are outstanding. Magnesium welds easily, is machinable and recyclable. Its melting point is 648.8°C. When exposed to air, magnesium tarnishes and forms a thin oxide coating.

Magnesium is one third lighter than aluminum. It is widely used in alloys with zinc, silicon, copper, aluminum and zirconium. Improvements in strength, vibration absorption, durability, corrosion resistance and weight savings are often achieved. Common applications are for automotive/truck components, electronic devices and aerospace parts including:

- Engine components

- Tablet computers

- Mobile phones

- Electric drills

- Steering components

- Instrument panels

- Transmission casings

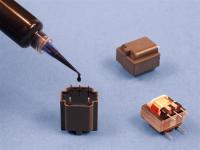

Master Bond formulates adhesive products designed to bond magnesium to magnesium and magnesium to dissimilar substrates.

Read our guide to learn more about proper surface preparation for bonding metals.

Consideration for Bonding Magnesium Substrates

|

Supreme 3AOHT One component, fast heat curing system. Can withstand rigorous thermal cycling. Thermally conductive, electrically insulative. Paste viscosity. Serviceable up to 350°F. |

|

EP30D-7 Urethane-modified epoxy system. Superior toughness and abrasion resistance. Cures at room temperatures. Compound flows easily and smoothly. Versatile cure schedule. |

|

EP121AO Thermally conductive, electrically insulative. Long working life. Outstanding dimensional stability. Superb heat resistance. Low coefficient of thermal expansion. Passes NASA low outgassing tests. Very long open time. Ideally suited for potting applications. Serviceable from -60°F to +500°F. Medium viscosity. |

|

EP33CLV Room temperature curing epoxy adhesive features high thermal stability. Excellent chemical resistance properties. High bond strength. Volume resistivity o >1014 ohm-cm. Withstands thermal cycling. Serviceable from -60°F to +450°F. Successfully tested for 1,000 hours 85°C/85% RH. One to one mix ratio by volume. Low viscosity. |

|

EP46HT-2ND2 Two part non-drip epoxy paste. Resists long term exposure from -100°F to +550°F. Superior peel strength. Protects against exposure to oils, fuels, hydrocarbons, acids, bases, solvents. Withstands thermal cycling and shock. |