Master Bond employs advanced, state of the art testing methods to ensure accurate, repeatable, and reproducible strength measurements. Strict adherence to material and process specifications is integral for meeting high quality standards. Master Bond mechanical testing equipment is frequently used for performing tensile and shear tests.

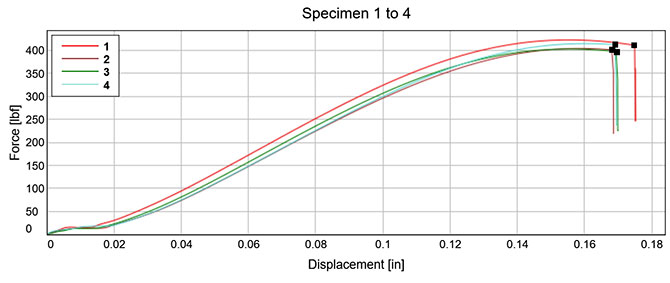

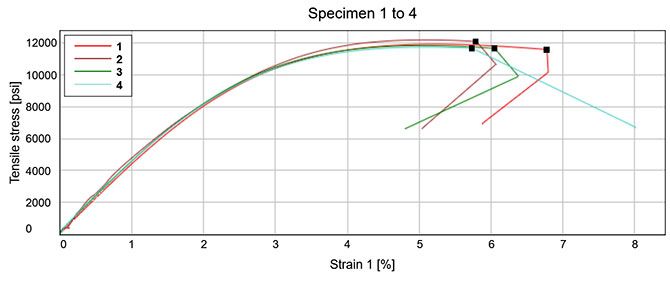

To illustrate, below you can see the curves that were obtained from the tensile testing of Master Bond epoxy EP42HT-2MED. This tensile test is based on ASTM D638 - 14 Standard Test Method for Tensile Properties of Plastics.

Graph 1: Force vs. Displacement

Graph 2: Tensile Stress vs. Strain

In a tensile test, the material by itself is clamped on both ends and pulled apart at a fixed speed. The force that the specimen must support, or the reaction force, is then measured and plotted as a result of the displacement. This force as a function of displacement is shown in the first graph. These values are then converted into the stress-strain curve shown in the second graph. This one represents the stress that the material must withstand when it is subject to a specific amount of strain.

Strength information like this can help engineers decide which products would be the best candidates to evaluate. However, testing would ultimately have to be performed in the context of an application, to gauge feasibility and ensure precise suitability. Factors such as the substrates being bonded, mechanical forces involved, and operating conditions such as temperatures, thermal cycling, and chemical exposure will have an impact on the results. It is important to note that processing of the adhesive plays an essential role in optimizing adhesion and product functionality. Optimal performance can be achieved by following the appropriate procedures for surface preparation, application of the adhesive, and curing.

To perform such tensile testing, Master Bond employs the Instron Model 3367 Dual-Column Universal Testing System in conjunction with Bluehill LE Software. Many Master Bond epoxies and other chemistries exhibit outstanding physical strength properties for high performance bonding, sealing, coating, potting, and encapsulation. This equipment enables Master Bond the ability to quantitatively assess those strength properties.

Instron 3367 Universal Testing System

Disclaimer: The findings in this article are not meant to be used for specification purposes.

References:

Testing system: http://www.instron.us/-/media/literature-library/products/2011/06/3300-series-table-model.pdf?la=en-US

Bluehill software: http://www.instron.us/-/media/literature-library/products/2014/06/bluehill-le--testing-software.pdf?la=en-US

Instron 3300 Series: http://www.instron.us/en-us/products/testing-systems/universal-testing-systems/electromechanical/3300/3360-dual-column

High Lap Shear Strength Adhesives for Nylon

|

EP29LPSP Two part epoxy system with ultra low viscosity and remarkable cryogenic properties. Withstands rapid drop in temperature and is NASA low outgassing approved. Optically clear. Long working life. Low exotherm. Excellent resistance to acids, bases and many solvents. Outstanding electrical insulative properties. Service operating temperature range from 4K to +275°F. |

|

EP21TDCHT High strength, high temperature resistant, two part system with excellent bond strength and thermal cycling capabilities. Serviceable from -100°F to +350°F. Meets MIL-STD-883J Section 3.5.2 for thermal stability. Moderate viscosity. Superior toughness. Withstands vibration, impact, shock. Good dimensional stability. Convenient one to one mix ratio. Dependable electrical insulation properties. |

|

Supreme 11HT High peel and shear strength system. Convenient one to one mix ratio. Serviceable from -100°F to +400°F. Superior resistance to impact, thermal shock, vibration and stress fatigue cracking. Excellent toughness. Cures readily at room temperature. User friendly. Dependable dimensional stability. Readily machinable. |