Epoxies, elastomeric modified epoxies and silicones are now being used in specialty electronic and related applications where acoustic damping and amplification may be required. These systems are used as adhesives, sealants, coatings and encapsulants.

Sound Damping

Master Bond’s thermoset systems that offer damping properties are invariably rubber modified epoxies and silicones, in both one and two part formulations. These systems are used in a large array of acoustic resonators, noise canceling electronics, sound proofing devices and insulation systems. Master Bond can offer customized formulations to adjust the hardness properties to fit the needs of the system. Specialty products have been used in a number of Hemholtz type resonators.

Sound Amplification

These same kinds of materials can be used in acoustical applications where amplification is needed. Many of these involve contact transducers and piezoelectronic devices. Epoxies filled with ceramic or metals including tungsten are often “go to” products in these kinds of devices.

In certain instances, some devices might need amplification, and in other instances, these same instruments might need damping. Hearing aids, underwater sonar devices and pulse receivers among others, would require adhesives, sealants or potting materials that necessitate damping or amplifications.

Ultrasonic Applications

Ultrasounds are acoustic waves with frequencies that are higher than the human detectable range, which are used to detect objects and distances. This technology is used in a wide range of applications including medical imaging, detection of flaws in objects, oil and gas exploration and in many other chemical processes. The non-destructive nature of this technology makes it extremely unique.

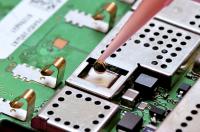

Ultrasound uses a piezoelectric actuator that generates the sound waves. These waves are then directed by an acoustic lens, filtered and matched through a backing layer and then detected to form an image. Such systems require special properties and Master Bond makes a wide range of products that are used in these specialty applications. Our custom formulated products are used for acoustical matching and blocking, thermal management, chip bonding, underfill as well as potting and coating PZT structures. Proper compounding with special resins and acoustic fillers will affect the product density, leading to improved image resolution for sensitive probes. These products are available in varying viscosities and hardness to meet the precise needs of acoustical engineers.

Learn about our adhesives, sealants and gasketing products for speaker assembly applications.

Most Popular Adhesives, Sealants, Coating and Potting Compounds for Acoustic Applications

|

Super Gel 9 Two part, room temperature curing, epoxy gel compound for sealing and encapsulation. Optically clear, soft and dimensionally stable. Ideal for retrievability. Two to one mix ratio by weight or volume. Low exotherm. Long working life. Low viscosity system. Unsurpassed thermal cycling and mechanical shock resistance. Used in conjunction with sensitive electronic and optical components. Serviceable from -100°F to +200°F. |

|

MasterSil 151 Optically clear, addition curing potting, encapsulation, sealing compound. Low shrinkage upon cure. Resists up to +400°F [+204°C]. Shore A hardness 50-60. Highly resistant to water. Long pot life. |

|

Supreme 10AOHT One part, oven cured epoxy system with excellent thermal conductivity and superb resistance to thermal cycling. Primarily used for bonding of heat sinks and sensors where heat transfer is desirable. Serviceable from 4k to +400°F. Convenient processing. |

|

EP30LTE Thermally conductive, electrically insulative epoxy. Has low thermal expansion coefficient. Superior dimensional stability. Good flow properties. Exceptionally low shrinkage upon cure. Service operating temperature range from -100°F to +250°F. Adheres well to similar and dissimilar substrates. |