Urethane modified compounds were developed by Master Bond to solve design, manufacturing and specialty applications across a broad range of industries. They offer a unique blend of properties for structural bonding, coating, sealing and potting applications. These isocyanate-free, 100% solvent free formulations offer better toughness and compliance when compared to many epoxies. They are especially useful when strength, flexibility, abrasion resistance, fast curing and chemical resistance properties are needed.

Advantages of Urethane Modified Adhesives

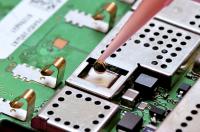

Two component urethane modified adhesives maintain their high peel and shear strength when bonding similar and dissimilar substrates, such as metals, plastics, composites, ceramics, and rubbers. In fact, they are noted for their ability to adhere well to many flexible substrates.

These compounds have minimal shrinkage upon cure, good elongation, and offer resistance to harsh environmental conditions. They are often used to bond substrates with different CTE's exposed to temperature cycling. Due to their superior cohesive strength properties, they are employed in numerous light weighting applications. This has enabled manufacturers of aircrafts, autos, trucks, boats, locomotives, and mining as well as medical equipment to improve energy efficiency and lower expenses

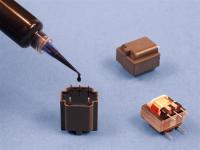

Select soft, resilient gel formulations can be used in acoustical applications where damping characteristics are beneficial. Some of these hybrid epoxy urethane systems are easy to remove and ideal for retrievability. Select grades have long working life and are ideal for encapsulation. Sealing is desirable for sensitive electronic components. Dimensional stability of these compositions is exceptional. Additionally, thermally conductive/electrically insulative systems have outstanding heat dissipation characteristics. Other products display optical clarity, cryogenic serviceability and unmatched abrasion/wear resistant properties.

Curing and Application for Urethane Modified Systems

Master Bond two component isocyanate- and solvent-free urethane modified adhesive systems exhibit versatile cure schedules at room or elevated temperatures. Fast curing compositions have enabled manufacturers to increase productivity and profitability, and have been used in countless indoor and outdoor applications.

These systems are also available in low, medium and gap filling, thixotropic paste viscosities. Free flowing grades are ideal for potting and encapsulation. Products can be applied with manual applicators or meter mix dispensing equipment and are available for use in a range of sizes and colors including convenient dispensing in special packaging such as pre-measured double barrel cartridges, flexible divider pouches (FlexiPak®).

Some of Master Bond’s Most Popular Urethane Modified Epoxy Systems

|

Super Gel 9 Two part, room temperature curing, epoxy gel compound for sealing and encapsulation. Optically clear, soft and dimensionally stable. Ideal for retrievability. Two to one mix ratio by weight or volume. Low exotherm. Long working life. Low viscosity system. Unsurpassed thermal cycling and mechanical shock resistance. Used in conjunction with sensitive electronic and optical components. Serviceable from -100°F to +200°F. |

|

Two part, room temperature curing, lower viscosity system used primarily for potting and encapsulation applications. Excellent thermal cycling properties along with shock and vibration resistance. Low exotherm and long working life. Superb abrasion resistance and electrical insulation characteristics. Repairable. Serviceable from 4K to +250°F. |

|

EP30D-7 Urethane-modified epoxy system. Superior toughness and abrasion resistance. Cures at room temperatures. Compound flows easily and smoothly. Versatile cure schedule. |

|

EP21DP12 Flexible two component epoxy for bonding, sealing, casting, potting. Urethane modified epoxy, 100% reactive. Resistant to thermal cycling. Serviceable from -100°F to +250°F. Available in many colors. |

|

EP30DP-NV Two part, room temperature curing, lower viscosity system used primarily for potting and encapsulation applications. Excellent thermal cycling properties along with shock and vibration resistance. Low exotherm and long working life. Superb abrasion resistance and electrical insulation characteristics. Repairable. Serviceable from 4K to +250°F. |