Two component epoxy system for bonding, sealing and coating applications

Key Features

- Very high temperature resistance

- Robust resistance to aggressive chemicals

- Very long open time

- Good flow properties

Product Description

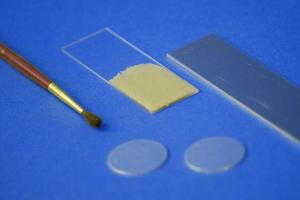

Master Bond EP35SP Type V is a two component epoxy system specially formulated to resist higher temperatures and aggressive chemicals. This lower viscosity material has an easy to use 100 to 50 mix ratio by weight. It will not cure at room temperature and it has an exceptionally long working life, far exceeding 24 hours. Although, it is slightly exothermic, it can be cured in sections exceeding 1/4 inch thick. Particular attention should be paid to the curing schedule. The main attribute of EP35SP Type V is as a high temperature resistant structural type adhesive, although it has many other outstanding properties as well. In this context, it can be used for filament winding, tooling compounds along with bonding composites and pultruded structures. As mentioned previously, it bonds well to a wide variety of substrates, including metals, composites, glass and many plastics. EP35SP Type V is highly resistant to water, oils, acids, bases and solvents. It has top notch physical strength properties and is a superior electrical insulator. The color of Part A is gray, and Part B is amber. The service temperature range for this system is -80°F to +500°F. EP35SP Type V is specified in many applications in aerospace, electronics, optical and specialty OEM, where the special combination of properties described above is needed.

Product Advantages

- Lower viscosity; very long open time

- Superb adhesion to a wide variety of substrates

- Ample physical strength properties

- Terrific resistance to aggressive chemicals especially acids, bases and petroleum related

- Commanding high temperature serviceability

- Excellent compatibility with filament winding and bonding composites

Packaging

EP35SP Type V is available is various sizes and units to accommodate customer's needs.